Foundry Automation

Our goal is the optimization of foundry processes: with optimally coordinated tools, machinery and equipment for the application of release agent, for handling and controlling, marking, cooling and transporting die-cast parts.

Our customers benefit from the expertise of our experienced designers and application engineers.

We focus on producing consistent high quality castings, reducing cycle times and minimizing consumtion of release agent.

Applicating Release Agent

Spraying the die-cast mould with release agent serves multiple purposes: the release film facilitates removing the cast parts from the mould and lubricates slides and ejectors. The spray system also cools the mould if external cooling is required,

Spraying Technology

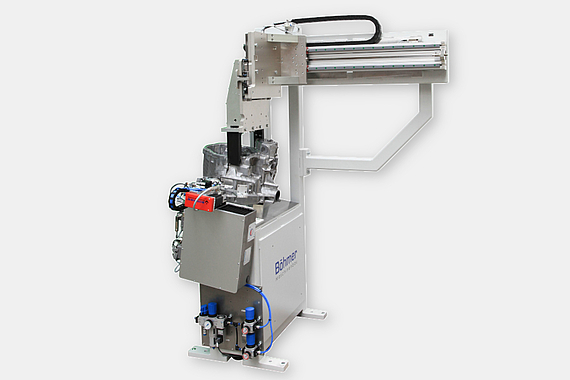

Mixing and Dosing Release Agent

The line of release agent mixing systems ranges from single stations to complete central-mixing plants with a capacity of up to 10,000 litres / hour.

All release agent mixing systems are custom-designed to meet your needs and are realised with the use of proven components.

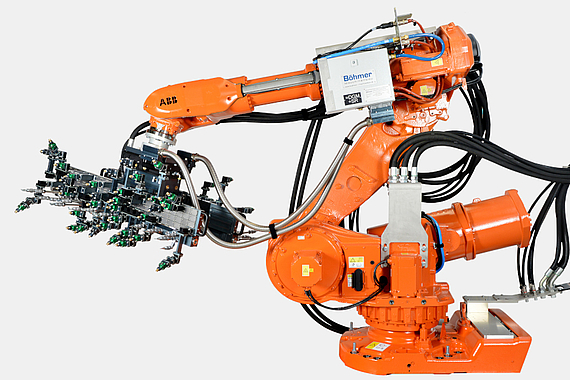

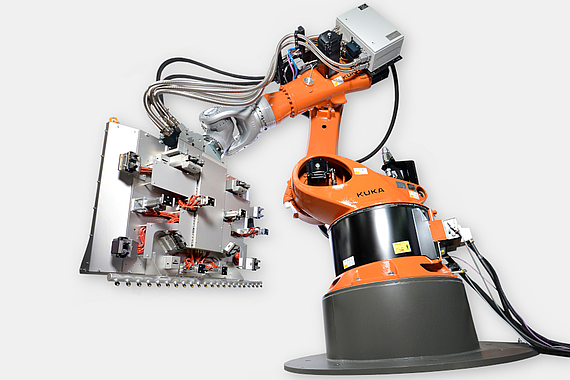

Gripping and Handling Parts

Regardless of the workpiece size and weight, we develop grippers for all foundry automation tasks.

These products range from the simple sprue grippers to contour grippers and combination grippers for insertion and removal.

Our product line also includes hydraulic grippers and vacuum grippers.

Marking and Controlling Parts

High-quality cast products require documentation of the casting data. For this purpose we provide part-marking stations with the labelling systems of all major manufacturers. Furthermore, we offer foundry-grade vision systems for parts inspection and control of the marking quality.

This equipment is topped off by conventional systems for component completeness checks using laser or infrared sensors.

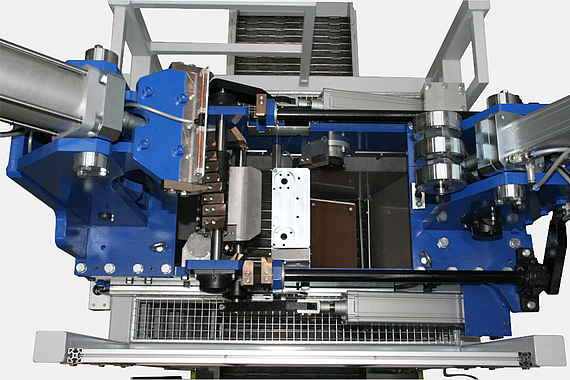

Rough Deburring Stations

Economic die-casting processes require a rethinking, also with regard to the deburring of components.

Our deburring stations forgo the use of hydraulic components, and therefore require only a conventional compressed air connection.

Through the use of segmented blades, mechanical loading during deburring is kept to a minimum, and the adaptation to changing component geometries is made possible by reworking or the replacement of individual blades.

Melt-Dosing

In order to adhere to our principle of reproducibility combined with high availability when it comes to melt dosing, we created a ladle for attachment to our linear devices or to a robot.

Melt-Dosing Technology

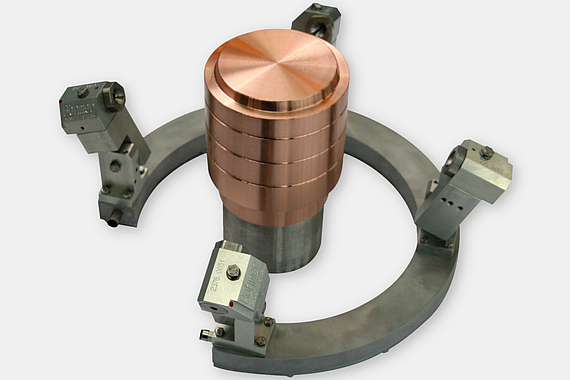

Shot Plunger Lubrication

Our piston lubrication systems emerged from our many years of experience in spraying liquids with a high solid content.

All versions are based on the same system and consist of a material pressure vessel and the proven BÖHMER micro-nozzles in a special design with a cleaning needle. This cleaning needle penetrates the nozzle orifice during each closing stroke, thus ensuring reliable operation even with nozzle diameters of less than 1 mm and even when using graphite lubricants.

In order to achieve a uniform coating here, the piston lubricant is applied at low pressure and supplemented with atomisation.

Shot Plunger Lubrication

Our piston lubrication systems emerged from our many years of experience in spraying liquids with a high solid content.

All versions are based on the same system and consist of a material pressure vessel and the proven BÖHMER micro-nozzles in a special design with a cleaning needle. This cleaning needle penetrates the nozzle orifice during each closing stroke, thus ensuring reliable operation even with nozzle diameters of less than 1 mm and even when using graphite lubricants.

In order to achieve a uniform coating here, the piston lubricant is applied at low pressure and supplemented with atomisation.

Questions about Foundry Automation?

Send us your inquiry and we will get in contact with you:

Maschinenbau Böhmer GmbH

Foundry Automation

Industriestrasse 15

57520 Steinebach

GERMANY

Phone: +49 2747 92 36 0

Email: sales@boehmer-maschinenbau.de