Gripping Technology

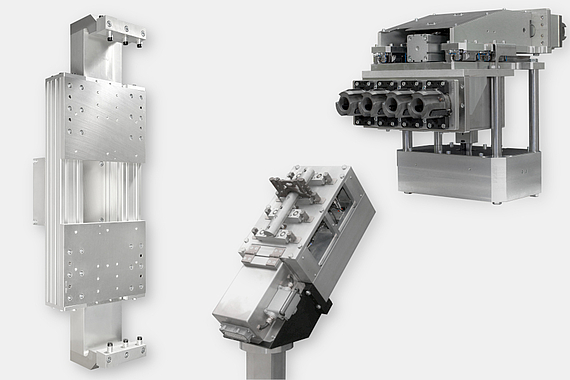

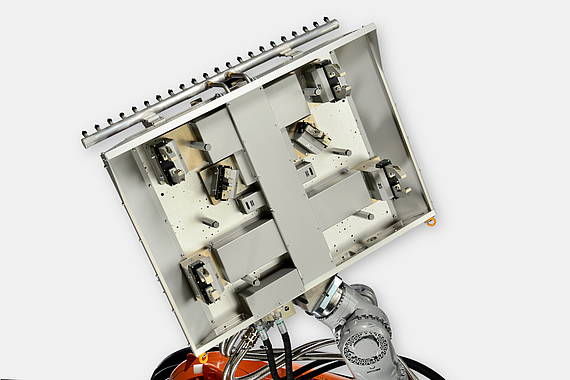

Regardless of the workpiece size and weight, we develop grippers for all foundry automation tasks.

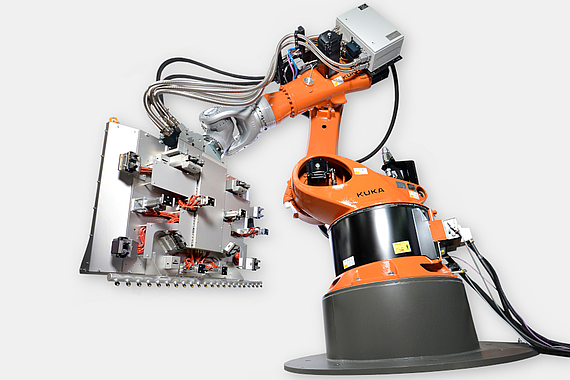

These products range from the simple sprue gripper to contour grippers and combination grippers for insertion and removal.

Our product line also includes hydraulic grippers and vacuum grippers.

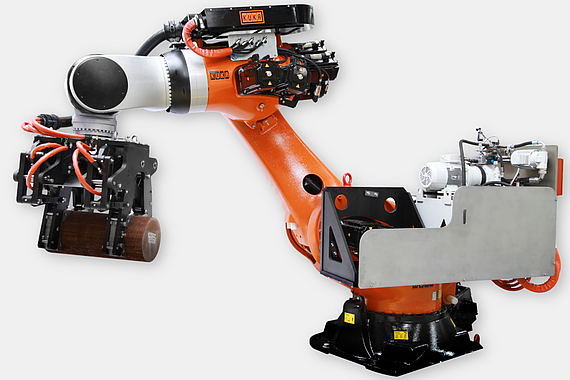

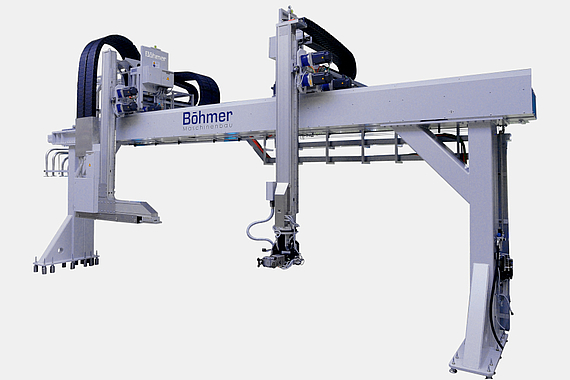

[Translate to Englisch:] Extraction and Handling Robots

[Translate to Englisch:]

Robots from all manufacturers (t.ex. ABB, Fanuc, KUKA, Kawasaki) can be used. The robots are equiped with our installation kit and our gripper. We also offer the respective control, installation and programming specifically for the diecast part.