Spraying Technology

Wetting the die casting mold with release agent has a decisive influence on the product quality of the die cast parts. The application of release agent should:

- Facilitate the release of the casting from the mold

- Increase mold life

- Minimize scrap

- Ensure process reliability

- Cool the die, especially in exposed areas such as cores or pins

- Lubricate moving parts (slides, ejectors)

We offer tailor-made solutions for every application: from simply replacing the spraying tool to installation kits for robotic spraying systems or linear spraying units to the installation of release agent supply systems.

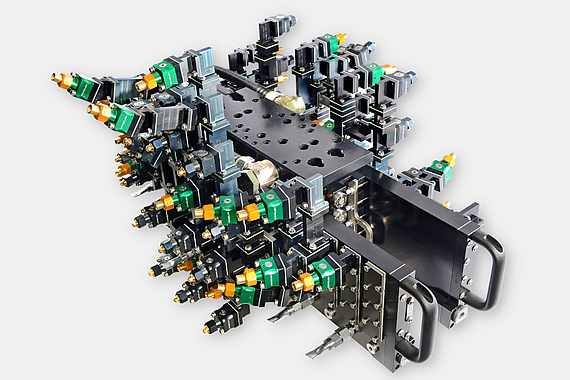

Spray Tools

To ensure the best possible performance, Böhmer spray tools are custom desinged to suit the application in terms of dimensions, number of spray circuits, and quantity and arrangement of spray nozzles. Focussing on the individual requirements of our customers allows us to optimize the spray process, effectively reducing release agent consumption and cycle time

Designing our spray tools based on the simulation of the spraying process does considerably shorten commissioning and optimization times on site.

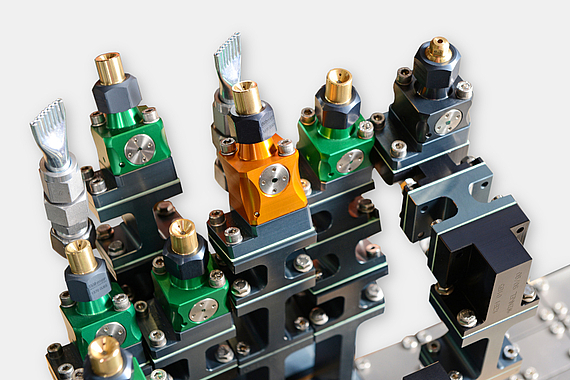

Spray Heads

High pressure spraying for efficient form cooling, micro spraying for optimum coating or spraying minimal defined amounts of release agent: Maschinenbau Böhmer offers a flexible selection of spray heads for all applications.

Spray Heads

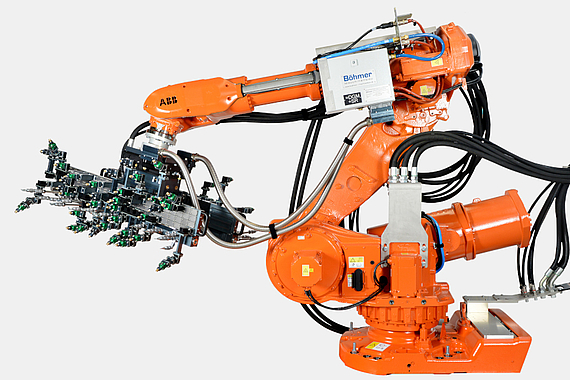

Spraying Machines and Robots

We offer complete robotic spraying systems regardless of the robot manufacturer (e.g. ABB, FANUC, KUKA). Our range of services includes robots, spraying tools and controls, in addition to the commissioning and component-specific programming.

Spraying Machines

Release Agent Mixing and Dosing

Release agents prevent die-cast parts from sticking to the die cast form. The most common types of release agent are water-based cooling lubricants. Maschinenbau Böhmer's release agent mixing systems and spray controls guarantee reliable mixing ratios.

Our experienced application engineers optimize the release agent application for your specific process.